Why ERP is must require for manufacturing and processing industries in modern business era?

Hello All,

The manufacturing industry is extremely dynamic, innovative and competitive in nature which makes it imperative for such businesses to possess an integrated solution which can give following intangible benefit to tech-savvy enterprise:

- Enhance efficiency

- Diminish costs

- Increase sales and profitability.

- Enables the organization to make accurate, informed and strategic decisions.

- Better utilisation of Enterprise tangible and intangible resources.

An enterprise resource planning system could be the solution to all or any these requirements.

With an ERP i.e., Dynamics 365 Business Central you can integrate, streamline and manage following aspect of manufacturing process and your business

- Planning,

- Scheduling,

- Inventory Management

- Distribution of resource at needy location

- Financial management

- Ensuring companies can respond quickly to new and changing demands and having the ability to provide customers what they need and when they want it.

Manufacturers who are looking to increase performance and efficiency should give Dynamics 365 BC an in-depth look.

DYNAMICS 365 BUSINESS CENTRAL

About D365 Business Central:

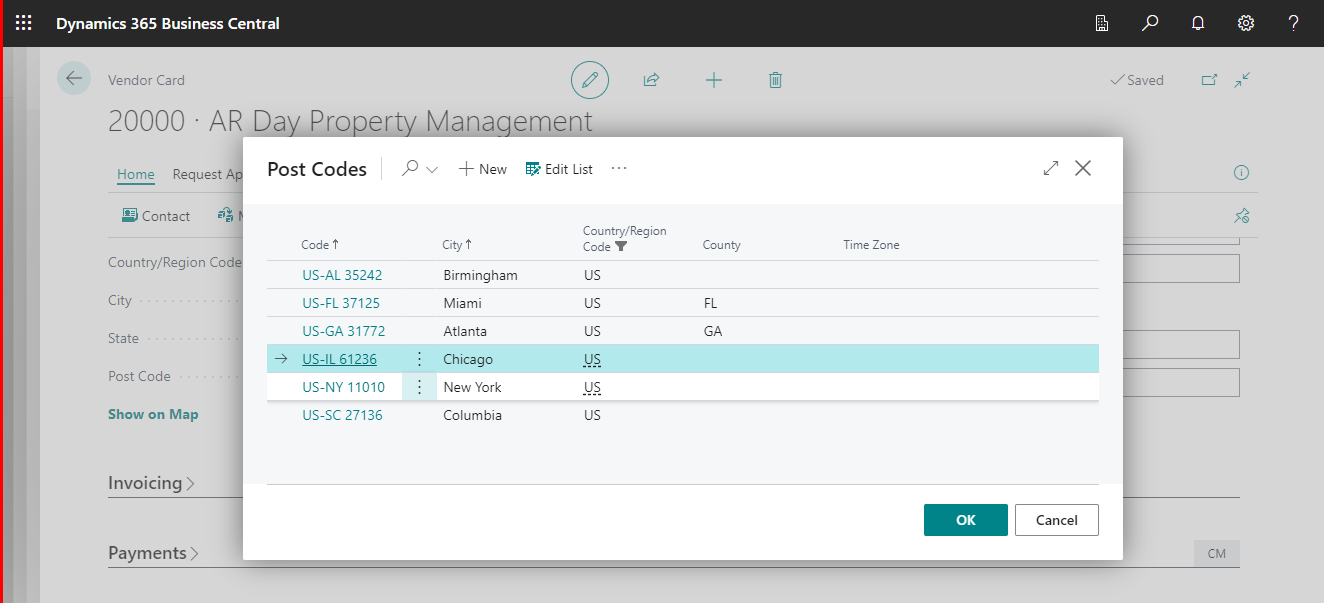

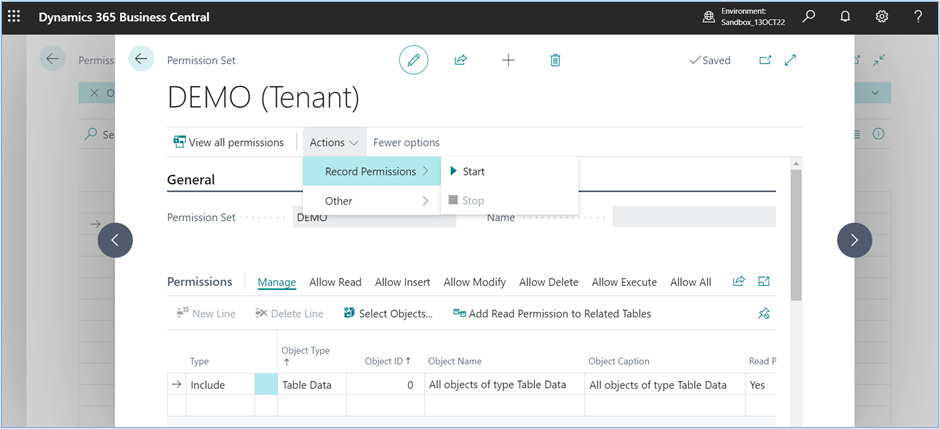

Dynamics 365 Business Central is a cloud-based ERP solution designed especially for SMBs and enterprise features everything for an organization business process. Business Central is fast to implement, easy to configure, development, implementation, and usefulness, listed below are some capabilities of the solution that may help you understand why manufacturing business must opt for it:

- Assembly Management:

Implement assembly orders to replenish assembly items. Forecast customer requirements for the unit’s bill of materials directly from dealers, blanket orders, and order lines in the assembly-to-order processes.

- Standard Cost Worksheet:

Give organization regulators a dependable and effective approach to keep up exact stock expenses. Work with standard cost refreshes in Business Central similarly you would in an Excel accounting page, prepare for cost updates without changing information until you are ready.

- Production Bill of Materials:

Make bills of materials and ascertain their standard expenses to get the actual trail of which purchased material used in which finished goods lot.

- Basic Capacity Planning:

Add capacities (work canter’s) to the manufacturing process. Install routings for production orders and material requirements planning. View loads and the assignment list for the limits.

- Machine Centers:

Include machine centers as functions in the manufacturing process. Manage functions for each machine or production resource on a detailed level for machine centers, and on a consolidated level for work centers.

- Version Management:

Make versions of manufacturing bills of materials (BOM’s) and routings.

- Customization:

The manufacturing module is customizable to add almost any capability if there are unique processes providing competitive advantage or increasing your profitability.

- Production Orders:

Make production orders and post consumption and output. Calculate net requirements based on production orders. Use a manual inventory planning tool as an alternative to automatic planning. Get visibility and tools to manually ready for request from sales lines and to make supply orders.

Hope above details made you interested to looks for above demonstrated ERP from fortune 500 company i.e. Microsoft. So if you want to interested for demo or for further details visit our website www.madhda.com